MDSLite

Our Lean, Out-of-the-Box Solution for Manufacturing

- As global opportunities expand and

adoption of the “Any Product, Any Plant” manufacturing strategy increases,

winning in today’s globally competitive marketplace requires partnering with a

proven company that helps you leverage industry best practices while supporting

process flexibility. Our MOM solution for discrete manufacturers delivers

visibility and control across your enterprise manufacturing operations and

supply chain, helping you drive global best practice and continuous improvement

while maximizing asset utilization:

• Easily adaptable to the specific requirements of different industrial processes

•The highly scalable platform delivers powerful capabilities and enables manufacturers to combine production

efficiency with production quality and production visibility to optimize their processes and significantly reduce their time-to-market

•MES capabilities and out-of-the-box features designed to support the unique processes and requirements of

sectors executing sequential discrete manufacturing functions in order to produce the desired product, particularly:

- Complex Assembly Manufacturing (high complexity, low volume)

- Job Shop Manufacturing (high complexity, low volume)

- Automated Repetitive Manufacturing

(configurable products, high volume)- The MDSLite solution addresses 80% of today’s manufacturing challenges at 20% cost with an implementation via agile from Start to Run in 8 weeks

• The solution helps to reduce costs and achieve the highest quality products while making compliance a by-product of

excellent manufacturing processes

Accelerate Innovation in the manufacturing domain with SBS’S MDSLite solution!

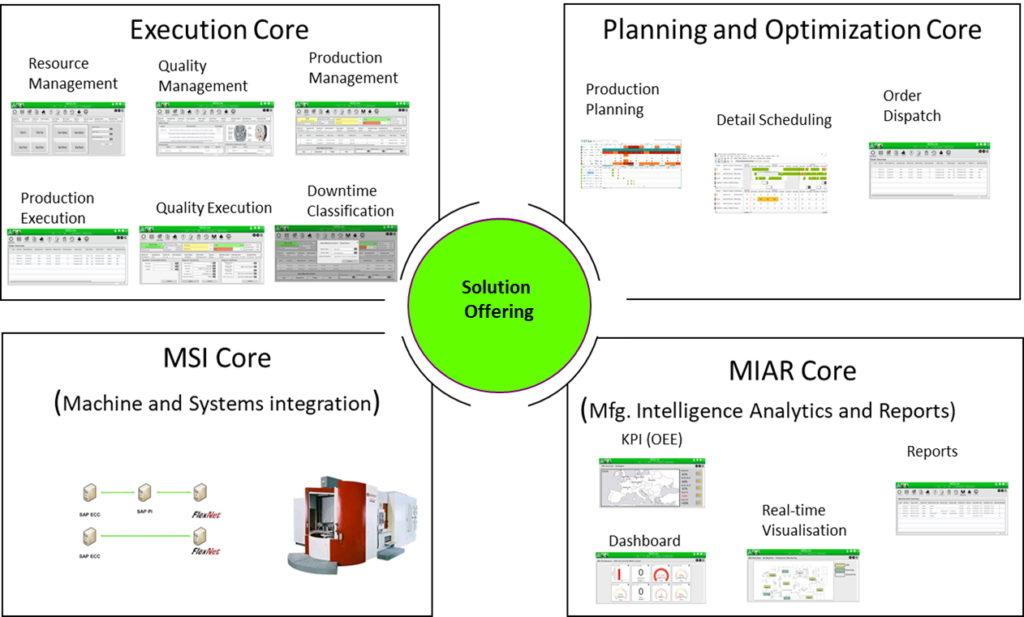

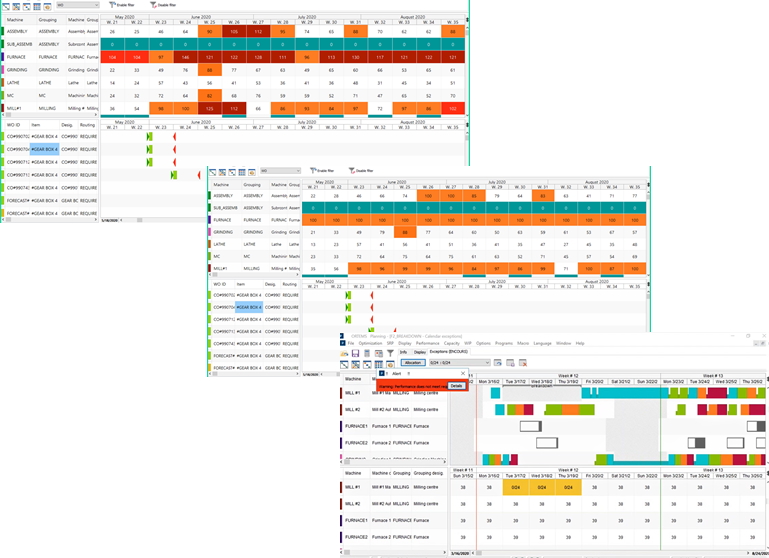

Planning and Optimization Core

MDSLite Planning and Optimization Core enables Advanced planning, Scheduling and optimization capabilities using Manufacturing Planner, Synchronized Resource Planner and Production Scheduler roles and solution is built on top of DELMIA Ortems product.

Anticipate plant capacity requirements

…by levelling the production plan vs load,

scenario analysis, capacity,

sales projections and new product introductions to

ensure maximum throughput

Deliver uninterrupted supply of finished goods

… through continuous synchronization of supplier production lines with customer assembly operations to reduce the risk of supply disruptions, material shortages and resulting penalties

Maximize and balance production lines

…that maximizes production utilization with optimized work order scheduling and sequencing while managing unplanned exceptions and events

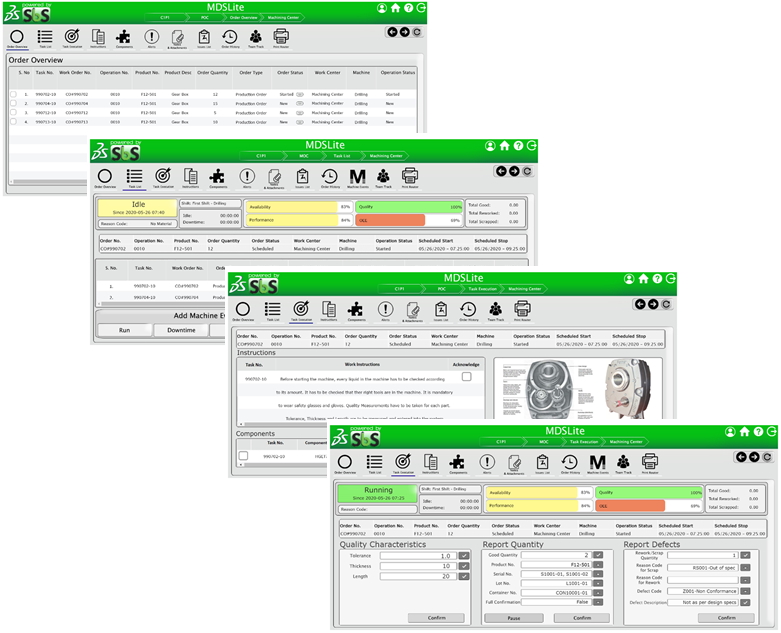

Execution Core

MDSLite Execution Core enables Manufacturing Operations Execution, Production, Quality, Time and Attendance and Warehouse capabilities on the plant floor, providing full visibility and synchronization.

Order Dispatch

…by assigning the right priorities to orders it is

guaranteed that the right orders are processed at the

right time by the right employees

Order Execution

… through electronic and real time status updates and data

collections, paperwork will be reduced and the agility of the organization

will be increased

Electronic Work Instructions & Quality Data

…will ensure alignment with R&D requirements and regulations. Engineering changes

will be immediately displayed on the floor and end to end traceability will be enabled.

Downtime classification

…measures objective production losses and indirect labor. This information will boost

the organizations continuous improvement process

Manufacturing Intelligence and Analytics (MIA) Core

MIA Core enables Manufacturing Intelligence, Analytics and Dashboards to provide visibility of OEE across Globe and drill down to specific areas and this solution is built on top of DELMIA Apriso – MPI and Dashboard Builder.

OEE Overview per region

…Organization wide KPI analysis – Only with a standardized MDS approach, KPI comparison across locations will be possible

Factory Visualization

… single source of truth for real time production events which will lead to a new

Level of transparency within the organization

Manufacturing KPI Dashboards

…will standardize and visualize the efficiency across the organization. All performance losses will be displayed according to the same logic and in real time

Machines and System Integration (MSI) Core

MSI Core enables integration across different systems (ERP, PLM, APS, MOM) to provide digital continuity across Manufacturing, Supply Chain and Engineering Design applications and processes.

ERP system Integration

…This core is built on top of DELMIA Apriso – Business Integrator application framework

…Enables integration with external ERP applications including SAP ECC, S4 HANA, MS Dynamics, MACPAC and any other legacy ERP applications to receive and send data between systems.

PLM System Integration

…This core enables to integrate process plans, designs, work instructions, master data between PLM and MES systems including various PLM applications including but not limited to Team Center, Enovia, Catia , SAP PLM and Solid works etc.

Advanced Planning and Scheduling integration

…MSI Core enables integration of master data and transactional data between MOM and APS applications such as ORTEMS, PREActor etc. to provide planned and scheduled data to MES system to start execution of orders on the shop floor and receive feedback from shop floor execution applications to proactively optimize planning and scheduling activities.

Machines Integration

…This core is configured to integrate with Machines and collect data from machines in real time using SCADA / OPC. This would help to enable automation and calculate OEE for machines automatically based on utilization of machines.

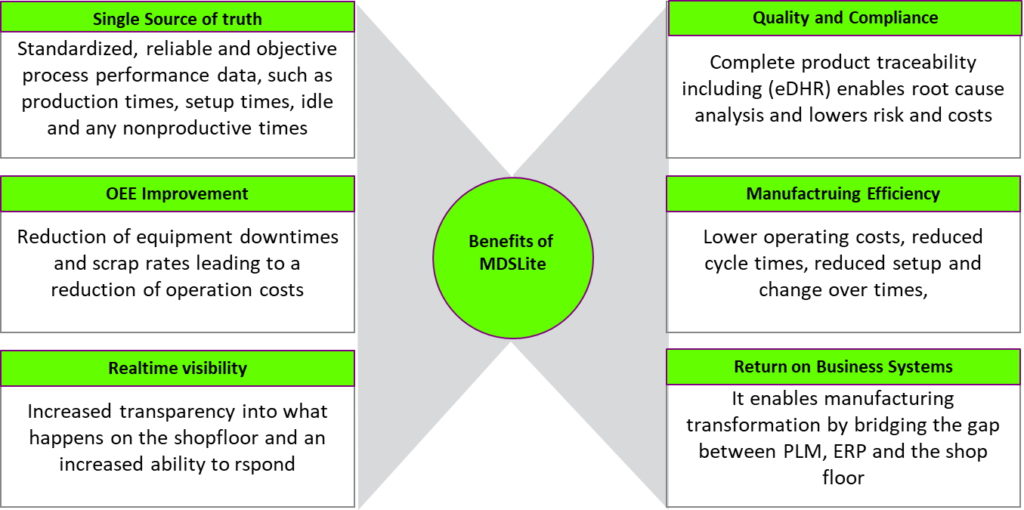

Key Benefits